Parts Setup (continued)

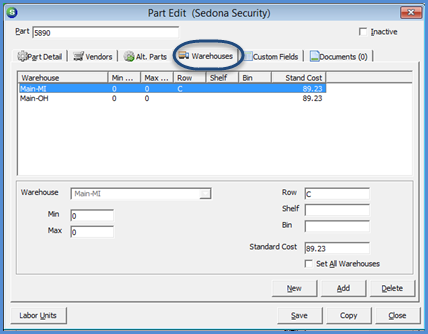

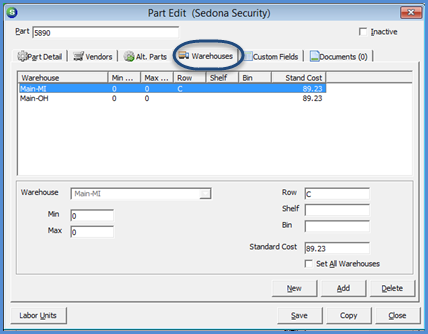

Warehouses

An unlimited number of Warehouses may be linked to a Part. The Warehouses feature only applies when the Stock Tracking feature has been activated in SedonaSetup. If Stock Tracking is not being used, one Main Warehouse is automatically created for processing inventory transactions. A Warehouse may be a main stocking location or vehicles for service technicians or installers.

8. Multiple Warehouses may be linked to the Part record. The first Warehouse selected and saved will be considered the primary stocking location. Click the Add button after entering all information for the warehouse. To add additional Warehouses to the list, click the New button and repeat the process until all needed Warehouse records are added to the list.

When finished entering all Warehouses, continue on to the Custom Fields form.

Warehouse* - Select a warehouse from the drop-down list.

Min, Max - These two fields are used if your company wants to maintain minimum and maximum stock levels for the part. The values entered into these fields is used by the Suggest Purchase Order function to determine when parts need to be reordered. These fields are optional.

Row, Shelf, Bin - These three fields are used to identify the stocking location of the part within the warehouse. Your may use one, or all of the stocking location fields. Values entered into these fields may be used as sorting selections when printing Physical Inventory Count Sheets. These fields are optional.

Standard Cost - This field is only available if your company is using the Standard Costing Method. Enter the cost at which the part will be valued.

Set All Warehouses - If the part is to be valued at the same Standard Cost in all warehouses linked to the part, select this option; highly recommended.

FRM 7006-1

Previous Page Page 11 of 13 Next Page